Ƙarfin Gwajin Aiki

Cikakken gwaji da aka yi amfani da shi a cikin sabon haɓaka samfur yana adana kuɗin abokin ciniki yayin da rage lokacin ƙirƙira. A farkon matakan, gwajin kewayawa, dubawar gani mai sarrafa kansa (AOI) da kuma Agilent 5DX dubawa suna ba da amsa mai mahimmanci wanda ke sauƙaƙe daidaitawa akan lokaci. Sannan ana yin gwajin aiki da aikace-aikace ga ƙayyadaddun abokin ciniki guda ɗaya kafin tsantsar tantance matsalolin muhalli ya tabbatar da amincin samfur. Lokacin da yazo don gabatar da sabon samfurin, POE suite na aiki da ƙarfin gwaji yana tabbatar da cewa gina shi daidai a karo na farko, da kuma samar da mafita wanda ya wuce tsammanin.

Gwajin Aiki:

Matakin Ƙarshe na Ƙarshe

Ana amfani da gwajin aiki (FCT) azaman matakin masana'anta na ƙarshe. Yana ba da ƙayyadaddun fassarori / gazawa akan kammala PCBs kafin a tura su. Manufar FCT a cikin masana'antu shine tabbatar da cewa kayan aikin samfur ba su da lahani waɗanda zasu iya, in ba haka ba, da lahani ga ingantaccen aikin samfurin a cikin aikace-aikacen tsarin.

A takaice, FCT tana tabbatar da ayyukan PCB da halayen sa. Yana da mahimmanci a jaddada cewa buƙatun gwajin aiki, haɓakawa, da hanyoyin sun bambanta sosai daga PCB zuwa PCB da tsarin zuwa tsarin.

Masu gwajin aiki galibi suna yin mu'amala da PCB a ƙarƙashin gwaji ta hanyar haɗin gefen sa ko wurin binciken gwaji. Wannan gwajin yana kwatanta yanayin lantarki na ƙarshe wanda za'a yi amfani da PCB a ciki.

Mafi na kowa nau'i na gwajin aiki yana tabbatar da cewa PCB yana aiki da kyau. Ƙarin ingantattun gwaje-gwajen ayyuka sun haɗa da hawan keke na PCB ta hanyar ɗimbin gwaje-gwajen aiki.

Fa'idodin Abokin Ciniki na Gwajin Aiki:

● Gwajin aiki yana kwatanta yanayin aiki don samfurin da ake gwadawa ta haka yana rage tsadar tsada ga abokin ciniki don samar da ainihin kayan gwaji.

● Yana kawar da buƙatar gwaje-gwajen tsarin tsada a wasu lokuta, wanda ke ceton OEM lokaci mai yawa da albarkatun kuɗi.

● Yana iya duba aikin samfurin a ko'ina daga 50% zuwa 100% na samfurin da ake aikawa ta haka yana rage lokaci da ƙoƙari akan OEM don dubawa da gyara shi.

● Injiniyoyin gwaji na ƙwararru na iya fitar da mafi yawan aiki daga gwajin aiki ta yadda zai zama mafi inganci kayan aiki gajeriyar gwajin tsarin.

Gwajin aiki yana haɓaka sauran nau'ikan gwaje-gwaje kamar ICT da gwajin bincike na tashi, yana sa samfurin ya fi ƙarfi da kuskure.

Gwajin aiki yana kwaikwayi ko kwaikwayi yanayin aiki na samfur don bincika daidai aikinsa. Muhallin ya ƙunshi duk wata na'ura da ke sadarwa da na'urar da ake gwadawa (DUT), misali, wutar lantarki na DUT ko kuma abubuwan da ake buƙata don sanya DUT yayi aiki yadda ya kamata.

PCB yana ƙarƙashin jerin sigina da kayan wuta. Ana kula da martani a takamaiman wurare don tabbatar da aiki daidai. Ana yin gwajin yawanci bisa ga injiniyan gwajin OEM, wanda ke bayyana ƙayyadaddun bayanai da hanyoyin gwaji. Wannan gwajin ya fi kyau a gano ƙimar abubuwan da ba daidai ba, gazawar aiki da gazawar ma'auni.

Gwajin software, wani lokacin ana kiransa firmware, yana bawa masu aikin layin samarwa damar yin gwajin aiki ta hanyar atomatik ta kwamfuta. Don yin wannan, software ɗin yana sadarwa tare da kayan aikin da za a iya tsarawa ta waje azaman na'ura mai mahimmanci na dijital, allon I/O, tashoshin sadarwa. Software da aka haɗe tare da kayan aiki da ke haɗa kayan aiki tare da DUT yana ba da damar yin FCT.

Dogara Akan Savvy EMS Bayar

Smart OEMs sun dogara da mashahurin mai bada EMS don haɗawa da gwaji azaman ɓangaren ƙirar samfurin sa da haɗuwa. Kamfanin EMS yana ƙara sassauƙa da yawa zuwa ma'ajiyar fasaha ta OEM. Gogaggen mai ba da sabis na EMS yana ƙira kuma yana haɗa samfuran PCB masu yawa don ƙungiyar abokan ciniki iri ɗaya daidai. Don haka, yana tara tarin ilimi, ƙwarewa da ƙwarewa fiye da abokan cinikin OEM ɗin su.

Abokan ciniki na OEM na iya amfana sosai ta hanyar aiki tare da mai ba da EMS mai ilimi. Babban dalili shine ƙwararren mai ba da EMS mai ƙwararru yana zana daga tushen ƙwarewarsa kuma yana ba da shawarwari masu mahimmanci da suka shafi dabaru da ƙa'idodi daban-daban. Sakamakon haka, mai ba da EMS yana iya kasancewa a cikin mafi kyawun matsayi don taimakawa OEM kimanta zaɓuɓɓukan gwajinsa kuma ya ba da shawarar mafi kyawun hanyoyin gwaji don haɓaka aikin samfur, ƙira, inganci, aminci, kuma mafi mahimmanci, farashi.

Gwajin binciken kai mai tashi/ƙasa-ƙasa

AXI - 2D da 3D dubawar X-ray mai sarrafa kansa

AOI - dubawa mai sarrafa kansa

ICT - gwajin kewayawa

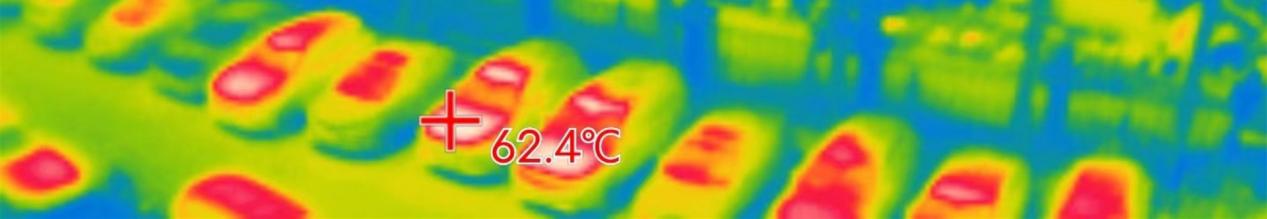

ESS - nazarin matsalolin muhalli

EVT - gwajin tabbatar da muhalli

FT - gwajin aiki da tsarin

CTO - saita-zuwa-oda

Binciken bincike da gazawa

PCBA Manufacturing & Gwaji

Samfurin mu na tushen PCBA yana ɗaukar majalisu da yawa, daga majalissar PCB guda ɗaya zuwa PCBAs waɗanda aka haɗa cikin ɗakunan ginin akwatin.

SMT, PTH, fasahar hadewa

Ultra fine pitch, QFP, BGA, μBGA, CBGA

Babban taron SMT

Shigar da PTH ta atomatik (axial, radial, tsoma)

Babu tsabta, ruwa mai ruwa da sarrafawa mara gubar

Kwarewar masana'antar RF

Ƙarfin tsarin aiki na gefe

Pressfit baya jirage & tsakiyar jirage

Shirye-shiryen na'ura

Rubutun conformal mai sarrafa kansa

Ayyukan Injiniya Na Mu (VES)

Ayyukan injiniya na ƙimar POE yana ba abokan cinikinmu damar haɓaka ƙirar samfuri da ingantaccen aiki. Muna mayar da hankali kan kowane bangare na tsarin ƙira da masana'anta - kimanta duk tasirin farashi, aiki, jadawalin shirin da buƙatun gabaɗaya

ICT Ta Yi Cikakken Gwaji

A cikin gwajin da'irar (ICT) ana amfani da su bisa ga al'ada akan samfuran balagagge, musamman a masana'antar kwangila. Yana amfani da na'urar gwajin kusoshi don samun dama ga wuraren gwaji da yawa a gefen ƙasa na PCB. Tare da isassun wuraren shiga, ICT na iya watsa siginar gwaji zuwa ciki da waje na PCBs a cikin babban gudun don aiwatar da kimanta abubuwan da aka haɗa da da'irori.

Gado na ƙusoshi kayan gwajin lantarki ne na gargajiya. Yana da fil masu yawa da aka saka a cikin ramuka, waɗanda aka daidaita su ta amfani da fitilun kayan aiki don yin

tuntuɓar wuraren gwaji akan allon da'ira da aka buga kuma ana haɗa su da na'urar auna ta wayoyi. Waɗannan na'urori sun ƙunshi ɗimbin ɗimbin ɗimbin ƙanana, masu ɗorawa pogo fil waɗanda ke yin hulɗa tare da kumburi ɗaya a cikin kewayar na'urar da ake gwadawa (DUT).

Ta hanyar danna DUT ƙasa akan gadon ƙusoshi, ana iya samun amintaccen tuntuɓar da sauri tare da ɗaruruwa kuma a wasu lokuta dubunnan wuraren gwaji ɗaya a cikin kewayen DUT. Na'urorin da aka gwada akan gadon gwajin ƙuso na iya nuna ƙaramar alama ko dimple wanda ya fito daga ƙwanƙwasa masu kaifi na pogo fil da aka yi amfani da su a cikin kayan aiki.

Yana ɗaukar 'yan makonni don ƙirƙirar ICT fixture da yin shirye-shiryensa. Kayan aiki na iya zama vacuum ko latsa ƙasa. Wuraren ɓangarorin na'ura suna ba da mafi kyawun karanta sigina tare da nau'in saukarwa. A gefe guda kuma, kayan aikin vacuum suna da tsada saboda manyan masana'anta. Kwancen ƙusoshi ko mai gwadawa a cikin kewayawa shine ya fi kowa kuma sananne a cikin yanayin masana'antar kwangila.

ICT yana ba abokin ciniki OEM fa'idodi kamar:

● Ko da yake ana buƙatar na'ura mai tsada, ICT tana ɗaukar gwajin 100% don a gano duk guntun wuta da ƙasa.

● Gwajin ICT yana ƙarfafa gwaji kuma yana kawar da buƙatun buƙatun abokin ciniki zuwa kusan ZERO.

● ICT baya ɗaukar lokaci mai tsawo don yin aiki, misali idan binciken jirgin sama ya ɗauki mintuna 20 ko makamancin haka, ICT na iya ɗaukar minti ɗaya ko makamancin haka.

● Dubawa da gano guntun wando, buɗewa, abubuwan da suka ɓace, abubuwan ƙima mara kyau, ɓangarorin da ba daidai ba, abubuwan da ba su da lahani da ɗigogi na yanzu a cikin kewayawa.

● Babban abin dogaro da cikakkiyar gwajin kama duk lahani na masana'anta, ƙira, da lahani.

● Ana samun dandalin gwaji a cikin Windows da UNIX, don haka ya sa ya zama duniya don yawancin buƙatun gwaji.

● Gwajin ci gaban dubawa da yanayin aiki yana dogara ne akan ma'auni don tsarin buɗewa tare da haɗawa da sauri cikin hanyoyin da abokin ciniki na OEM ya kasance.

ICT ita ce nau'in gwaji mafi wahala, wahala, da tsada. Koyaya, ICT ya dace don manyan samfuran da ke buƙatar samar da girma. Yana gudanar da siginar wuta don bincika matakan ƙarfin lantarki da ma'aunin juriya a kuɗaɗe daban-daban na allon. ICT yana da kyau a gano gazawar ma'auni, kurakuran ƙira da gazawar sassa.

Lokacin aikawa: Yuli-19-2021